The Hidden Cost of Oversizing

Cold snaps are a common phenomenon and something that needs to be dealt with in the heating business; however, is it really worth building an entire system to deal with one week every few years or is this mentality old fashioned?

Flawed Assumption

This flawed assumption of peak load paranoia is a very common problem when it comes to transitioning to heat pumps. People think the heat pump alone must be able to deal with every worst-case scenario, no matter how rare but this leads to inefficient systems with frequent problems due to weak loads for most of the year.

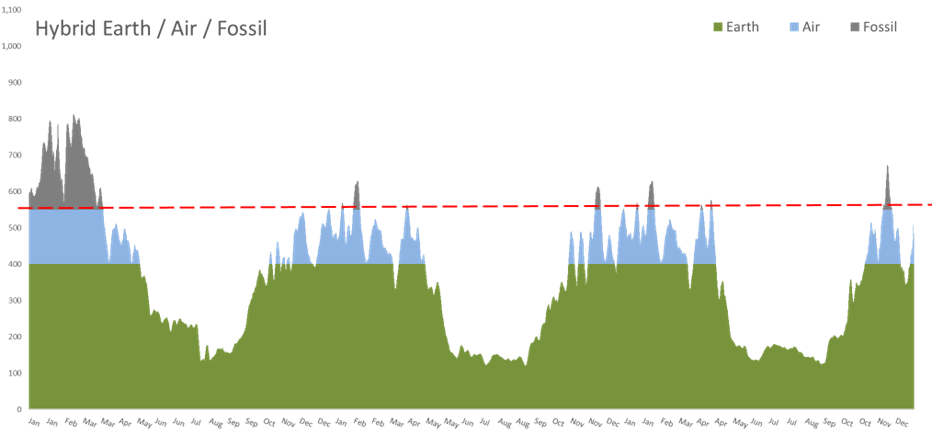

Figure 1: Four years of thermal demand per hour (kWh) data, with the energy sources shown in different colours

In Figure 1 the peaks in thermal demand that require fossil fuels to be used accounted for a few days of the year in most cases. It makes more sense to build the system smaller, cheaper and eliminate most of the carbon emissions.

Example: “80% of the heating load covered by geo-exchange = 95% of hours, with better overall system performance”. Covering that last 5% may make the system 20% bigger, a totally unnecessary expansion.

The consequences of oversizing include:

- Bigger borehole arrays = more cost, more land, longer payback

- Oversized plant = inefficient operation in Spring and Autumn (poor Coefficient of Performance (CoP))

- More in embodied carbon from larger builds

- Missed opportunity to blend in a low-cost auxiliary system

Smarter Approach: Hybrid Thinking

- Erda systems are designed for optimised load coverage

- Low-CoP peak demand can be met by:

- An auxiliary air source heat pump

- Existing small-capacity gas boiler for peaks

- Thermal stores if already present

Optimising for every day beats optimising for the coldest day of the decade. A right-sized system performs better, costs less, saving those resources for other buildings in the future, e.g. five buildings with a 95% reduction in emissions rather than four with 100% reduction. Eventually, this approach will get you to net zero faster.